A check valve prevents potentially damaging backflows to protect equipment like pumps and compressors. Non-return valves allow the flow of the fluid in one direction only and block reverse flows. This type of valves is available with cast and forged bodies (BS 1868, API 6D, API 602) and in several designs as swing, ball, lift, stop and piston designs.

Briefly said, a check valve is a protection device that prevents the fluid from flowing in an unwanted direction within the piping system or the pipeline (as backflows may damage upstream equipment).

How does a check valve work?

The valve lets the fluid flow in the desired direction only (if there is enough pressure), and blocks any flow in the opposite direction. Also, the valve closes automatically when the pressure drops. It is therefore critical that the valve is installed with a proper orientation!

Note that this type of valve accomplishes its scope without external forces or actuation. This is a key difference vs. gate or globe valves, that need an external force to work (level, wheel, gear or actuator).

The key specifications that cover this type of valve are:

BS 1868: standard type, in carbon and alloy steel.

API 6D: for pipelines.

API 602 / BS 5351: forged steel (swing, ball, piston).

API 603: stainless steel stop type.

ASME B16.34 (pressure and temperature ratings).

ASME B16.5/ASME B16.47 (flanged end connections).

ASME B16.25 (butt weld connections).

Cast steel valves are available with flanged and butt weld ends.

Forged, small size, valves are available with threaded and socket weld connections.

These valves are represented by the following symbol in piping P&ID diagrams: Symbol for check valve in P&ID diagram

Check valves are available in different types which accomplish the function described above with different disc (ball, clapet, piston, etc) designs. Let’s take a closer look to each type.

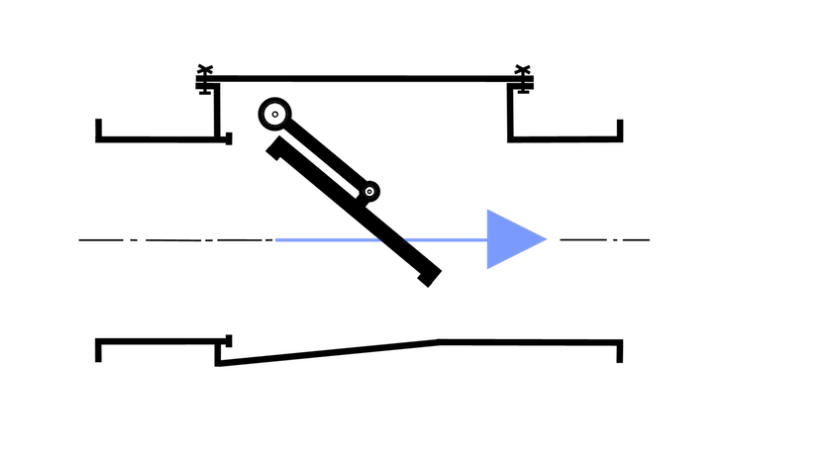

SWING CHECK VALVE

This type has the simplest design and operates via a metallic disc ("Clapet") attached to a hinge at the top. As the fluid passes through a swing valve, the valve is open. When a reverse flow occurs, the changes in motion as well as gravity help to pull down the disc, closing the valve and preventing backflows.

Swing valves are used for firefighting and flood prevention in sewage systems. They’re also designed to work with materials such as gas, liquids, and other types of media.

Stop-check can start, stop, and regulate the flow of fluids while preventing dangerous backflow that may damage other equipment like pumps and compressors.

When the pressure in the system is below a certain value, this valve closes automatically to blocks reverse flows. Generally, this type of valve has an external override control to close the passage of the fluid manually (similarly to a gate valve).

Stop-check valves are very common in power plants, boiler systems, and oil & gas refining, hydrocarbon processing, and high-pressure safety services.

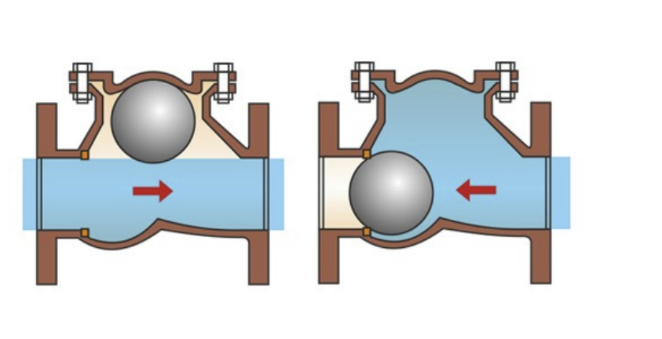

BALL CHECK VALVE

A ball check valve features a spherical ball positioned inside the body that opens and closes the passage of the fluid in only a wanted direction.

The ball rotates freely when the fluid passes through the pipeline in the desired direction. If the pipeline is subject to a pressure decrease or a reverse flow, the ball inside the valve moves towards the seat, sealing the passage. This design suits viscous fluids.

All check valves belong to the family of "lift valves", and have a seat design similar to globe valves.

A variant of the ball design is the so-called piston type. This type of valve is used for high-pressure services where the fluid can change direction suddently and with good force (this due to the fact that the disc is precisely guided and fits perfectly into the seat).

Ball and piston check valves can be installed both horizontally and vertically.

DUAL PLATE

Dual plate check valves, covered by the API 594 specification, are frequently used to protect pumps, compressors and other mechanical equipment.

PRESSURE SEAL

This type features a special design cover able to withstand high pressures.

A new check valve shall be installed anytime a new sump pump is placed into operation. This due to the fact that older protection valves may have been damaged by previous open/close operations or by corrosion and the risks of damaging a new sump pump exceed by far the cost of a new check valve!

A sump pump valve prevents backflows into the sump pump when the device is switched off by an operator or by an automated control system. Without a check valve, the fluid may return into the sump pump and oblige it to move the same fluid multiple times, burning it out prematurely.

Therefore, to extend the life cycle of a sump pump, a non-return valve should always be installed.

Post time: Oct-26-2019